□ A joint research team from the DGIST Nanotechnology Research Division led by Dr. Donghwan Kim and Dr. Jungmin Kim (President Kunwoo Lee) has developed an innovative permanent magnet manufacturing process that overcomes the limitations of conventional technology. The team’s breakthrough advances significantly the diffusion technology essential to improving magnetic performance, creating new possibilities for applications of high-efficiency magnets in green industries such as electric vehicles, wind turbines, and robotics.

□ With the rapid growth of electric vehicles and wind power generation fields, demand for powerful permanent magnets that can operate stably even at high temperatures is rapidly increasing. A prime example is neodymium (Nd-Fe-B) permanent magnets, which are widely used in electric vehicle motors. However, these magnets lose their magnetic performance under extreme heat and require the addition of heavy rare earth elements such as terbium (Tb) and dysprosium (Dy) to maintain their strength. The challenge is that these elements are rare and expensive.

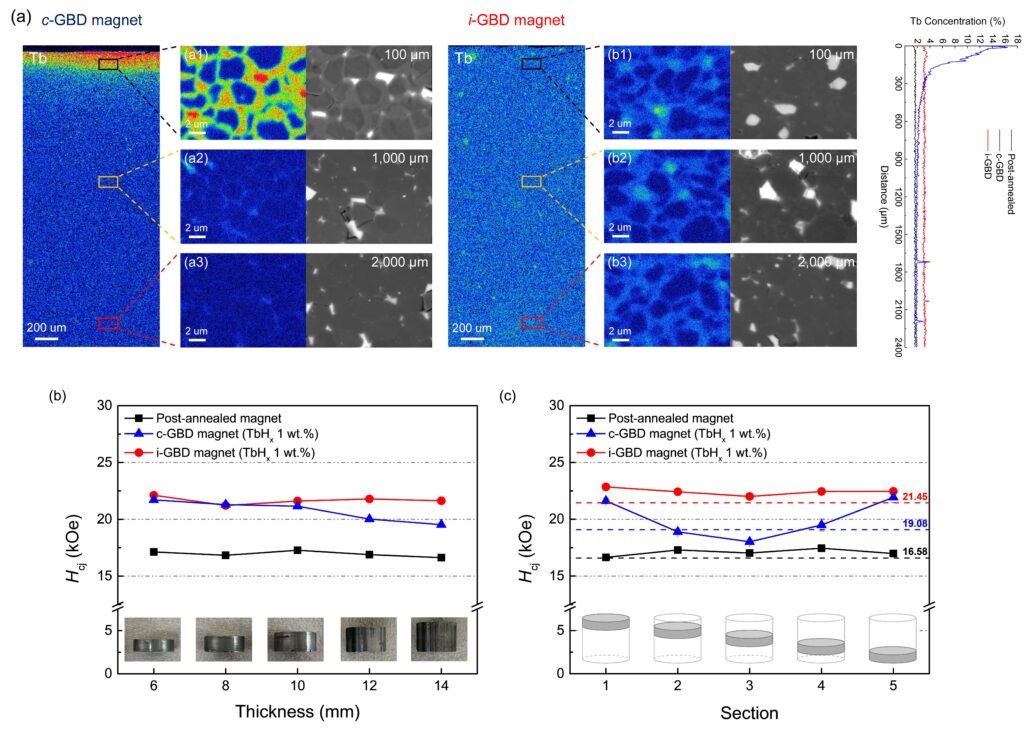

□ To address this problem, grain boundary diffusion processes are widely employed. This technology improves magnetic performance by infiltrating the surface of the magnet with a small amount of heavy rare earth material. However, diffusion in this process is limited to the surface layer and does not penetrate inside the magnet, making it difficult to apply to thick magnets.

□ To overcome this limitation, the research team combined an advanced manufacturing technique, spark plasma sintering, with a grain boundary diffusion process. Uniform diffusion throughout the magnet was achieved by pre-mixing the diffusion material during the manufacturing stage of the powder-based magnet. As a result, we were able to achieve a core-shell structure with a significantly deeper diffusion depth than with conventional methods, and the magnet’s magnetic performance was uniform and improved.

□ Remarkably, even when using the same amount of rare earth material, the new process achieved higher diffusion efficiency and significantly improved overall performance. This makes it possible to make the magnet smaller and lighter while maintaining strong magnetic force. It is expected to contribute to making electric vehicle motors smaller and lighter and improving energy efficiency. Furthermore, this process shows great potential for large-scale magnet applications.

□ Lead researcher Dr. Kim Dong-hwan said, “This research presents a method to overcome the limitations of conventional grain boundary diffusion technology and achieve uniform performance throughout the magnet.It will greatly contribute to the development of high-performance permanent magnets required in environmentally friendly energy industries such as electric vehicles and wind power generation.”

□ This research was supported by the DGIST Institutional Program, Kyungpook University Carbon Neutral Intelligent Energy System Regional Innovation Leading Research Center, and Songlim Advanced Industrial Co., Ltd. The research results have been registered as a domestic patent, and a US patent has also been applied for. The research results were published in the Journal of Alloys and Compounds, a leading international publication in the field of metal materials.