research design

In this study, we used process-based LCA to quantify the environmental impact of two different xenograft procedures, including a native cornea and a decellularized corneal scaffold that can be regenerated as an individual graft. These procedures were performed at the Khalifa University Faculty of Medicine and Health Sciences (KU CMHS) in Abu Dhabi, United Arab Emirates (UAE). The organization is one of the leading institutions involved in regenerative medicine in the UAE, generating hundreds of xenograft models each year and providing primary tissue engineering to address the significant and growing need for corneal transplantation. and stem cell-based tissue engineering. The functional unit of this procedure was a single heterogeneous corneal prosthesis model containing a single sheep eye.

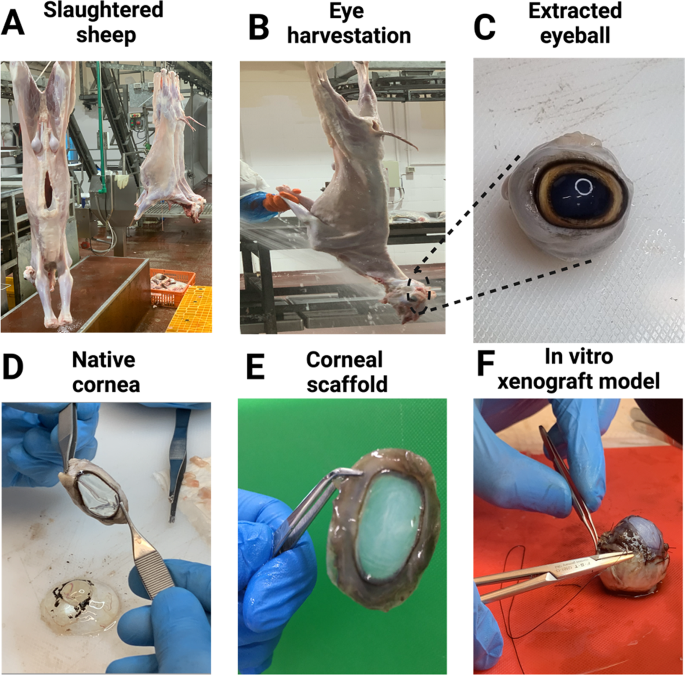

Xenograft corneal transplant model obtained from slaughterhouse waste

All tissues were collected from the Abu Dhabi automated slaughterhouse. The slaughterhouse is one of the largest slaughterhouses in the UAE and can accommodate approximately 37,000 sacrifices and carcasses. For our purposes, sheep eyes were collected from the animals immediately after sacrifice, transported to KU CMHS, and used to create xenografts for the in vitro transplantation model shown in Figure 1. The model consists of homogeneous natural cornea and tissue. – Manipulation of personalized xenografts derived from decellularization/recellularization techniques that are transplanted into eyes harvested from other animals. Detailed details regarding native and tissue engineering processes 3,4 and transplantation 27 are outlined in the literature. All experimental protocols were approved by the Animal Research Oversight Committee (AROC) of Khalifa University of Science and Technology. This study was also conducted in accordance with ARRIVE guidelines. All methods were performed in accordance with relevant guidelines and regulations.

Figure 1

Corneal xenografts generated from whole waste obtained from the Abu Dhabi Automated Slaughterhouse. (A) Image of a freshly slaughtered sheep, (B) A slaughterhouse worker preparing to remove a whole eye from an animal, (C) An enucleated eyeball, (D) A natural eye removed from an entire eye. Cornea, (E). Corneal scaffold produced from decellularization/recellularization technology, and (F). In vitro heterologous keratoplasty model.

Corneal processing and xenograft preparation

The protocols for processing both natural corneas and tissue-engineered corneal scaffolds used in this study were based on methodologies established in previous studies. Fresh sheep eyes were procured from Abu Dhabi Automated Slaughterhouse and transported to KU CMHS under sterile conditions. In previous studies, natural corneas were excised, cleaned with sterile saline, and treated with antibiotics to minimize contamination. These corneas were evaluated in their unmodified state, focusing on structural integrity, transparency, and biomechanical properties (see related previous studies).

We previously employed a decellularization process for tissue engineering corneal scaffolds using a 4% zwitterionic biosurfactant solution, followed by rigorous washing to remove residual surfactant. These decellularized scaffolds were analyzed through histological and polymerase chain reaction (PCR) assays to confirm the absence of cellular material and pathogens. The results of these evaluations provided the basis for evaluating the potential of decellularized corneas as xenografts28.

Although the current study did not directly replicate these experiments, we conducted a comparative life cycle analysis (LCA) and cost of natural corneal scaffolds derived from slaughterhouse waste and decellularized corneal scaffolds based on previously validated processes. A paired effect analysis (CEA) was performed. This analysis was used to assess the environmental and economic impact of utilizing these materials in clinical practice.

product life cycle model

The life cycle assessment (LCA) conducted in this study aimed to quantify the environmental impact of xenograft keratoplasty following a structured multi-step approach based on the ISO 14,040 framework . LCA includes four main stages: goal and scope definition, life cycle inventory (LCI), life cycle impact assessment (LCIA), and interpretation. Each parameter used in LCA is detailed below, based on how it is determined and evaluated.

Define goals and scope

The goal of the LCA was to evaluate the environmental impact of a single xenograft keratoplasty procedure, from tissue collection to postoperative patient care. The selected functional unit was chosen as the production of one pair of sheep-derived corneas for transplantation. The system boundaries were set to include all processes from harvesting, sterilizing, packaging, and transporting sheep tissue to end-of-life scenarios for performing operating room procedures and various keratoplasty procedures. Exclusions include environmental impacts beyond the control of the surgery itself, such as personal transportation of patients to the clinic and hospital energy use unrelated to the surgery. Sensitivity analyzes were conducted to assess the significance of these exclusions. All inputs were imputed by weights and normalized accordingly. Therefore, impacts related to the processing and packaging of meat, skin, and other products are not included in this study. The system boundaries are shown in Figure S1 in the Supplementary File. It is important to note that the thematic analysis only takes into account the imputed lifetime of the equipment used. Assumptions regarding the useful lives of inputs and their contribution percentages are provided in the appendix. Therefore, some inputs (such as drapes) were not considered in the analysis because their lifetime depends on the quality of the fabric and include inputs related to washing, ironing, and repacking, which are currently is beyond the scope of research.

Life Cycle Inventory (LCI)

The lifecycle inventory phase involves collecting quantitative data for each stage of the xenograft corneal transplant process. Each parameter was measured, estimated, or obtained from an existing LCA database, such as the Ecoinvent database. Data on sheep corneal extraction was collected, including energy usage, water consumption, and waste generation. Information about the sterilization process was obtained from hospital records, including energy usage, chemicals involved (e.g., ethylene oxide), and water consumption. The environmental footprint of the materials was obtained from Ecoinvent. The impact on transportation was calculated based on the distance the harvested corneal tissue traveled from the animal facility to the surgical center, taking into account the mode of transportation (i.e., refrigerated truck). Standard emissions data for transportation, such as fuel consumption and greenhouse gas emissions per kilometer driven, were used. Detailed data were collected on surgical instruments used, including disposable items (gloves, scalpels, sutures) and their disposal. Energy consumption (electricity for lighting, HVAC, and surgical equipment) was estimated using the hospital’s energy audit. Data on the generation of intraoperative waste (hazardous and non-hazardous substances) was also documented.

Life Cycle Impact Assessment (LCIA)

The LCIA phase used an impact assessment model to convert inventory data into environmental impacts. SimaPro software was used to estimate 18 midpoint metrics using the ReCiPe method with a hierarchical perspective. When individual input data were missing in the Ecoinvent database, published protocols were implemented based on chemical properties or functional similarities. These similarities were identified by the case study owners as appropriate to the scope of the study. The equation for the contribution of individual emissions in the system is given by Equation (1).

$$\:Process\:LCA=\sum\:_{i=1}^{n}{A}_{p\left(i\right)}\times\:{E}_{p\left( i\right)}$$

(1)

Here, Ap represents the input (i) to the supply chain according to the system boundary shown in Figure 1. This includes the extraction of raw materials, energy use, and production processes. n is the total number of inputs (i) and Ep is the emission intensity of the selected impact category outlined above for each input (i) to the supply chain. A detailed description of the LCA parameters is provided in the supplementary file.

interpretation

The final stage of the LCA involved interpreting the results to identify the most important factors in the environmental impact of xenograft keratoplasty. Sensitivity analyzes were conducted to investigate how changes in key parameters (transport distance, energy use, etc.) affect the overall results. Recommendations to reduce the environmental impact of xenograft keratoplasty were derived from this stage, focusing on areas such as optimizing transport logistics and improving the energy efficiency of sterilization processes.